We are engineers

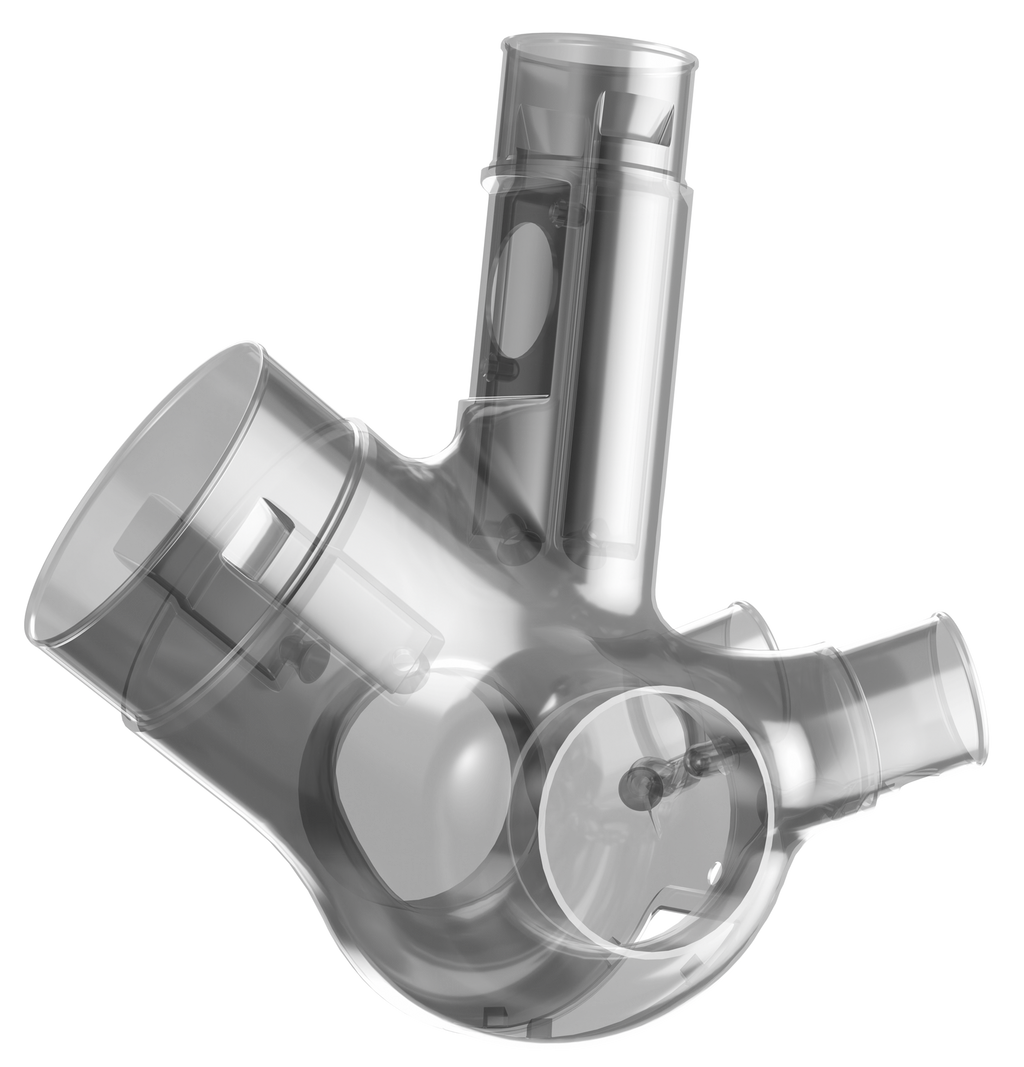

In the world of VER-TEC's high-tech manufacturing, everything revolves around precision, forces and the play of mechanics. Thinking through and designing innovative solutions is in our blood. We firmly believe that our products should adapt intuitively to people's needs - a philosophy that guides our daily work and forms the foundation of our corporate culture.